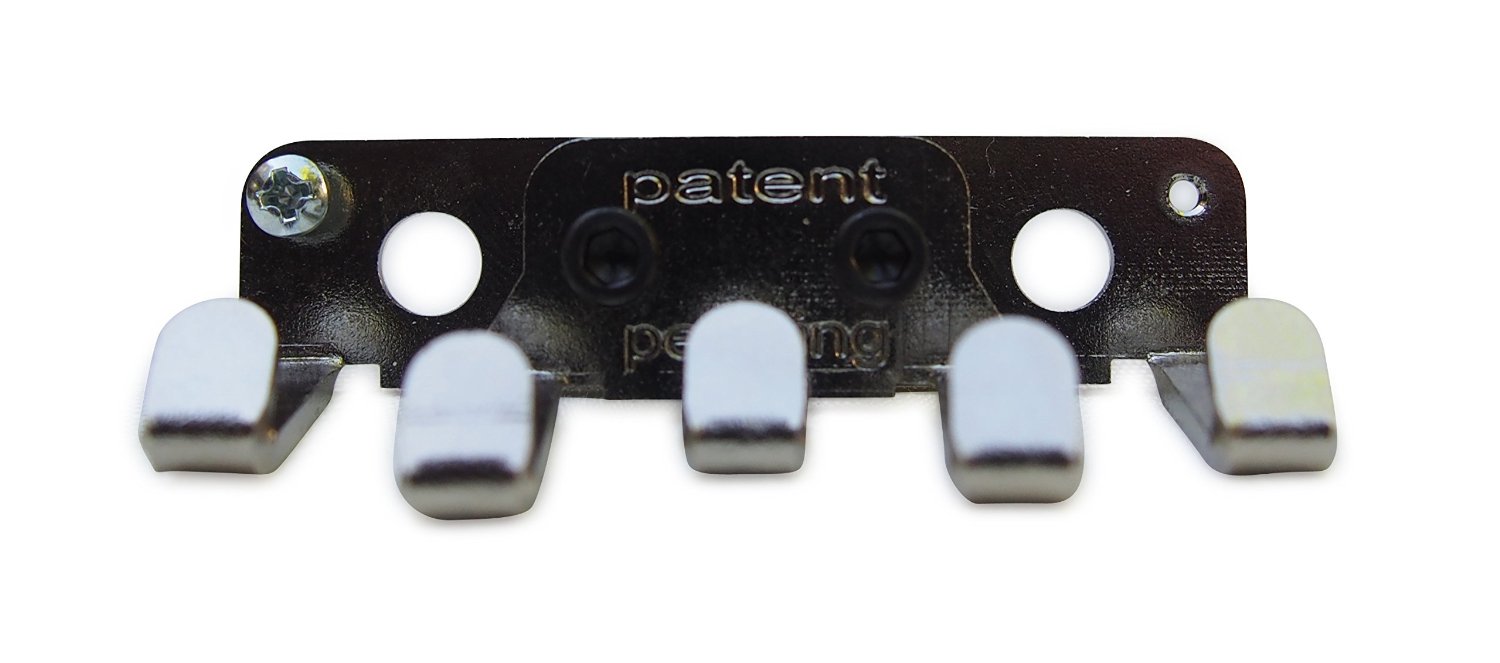

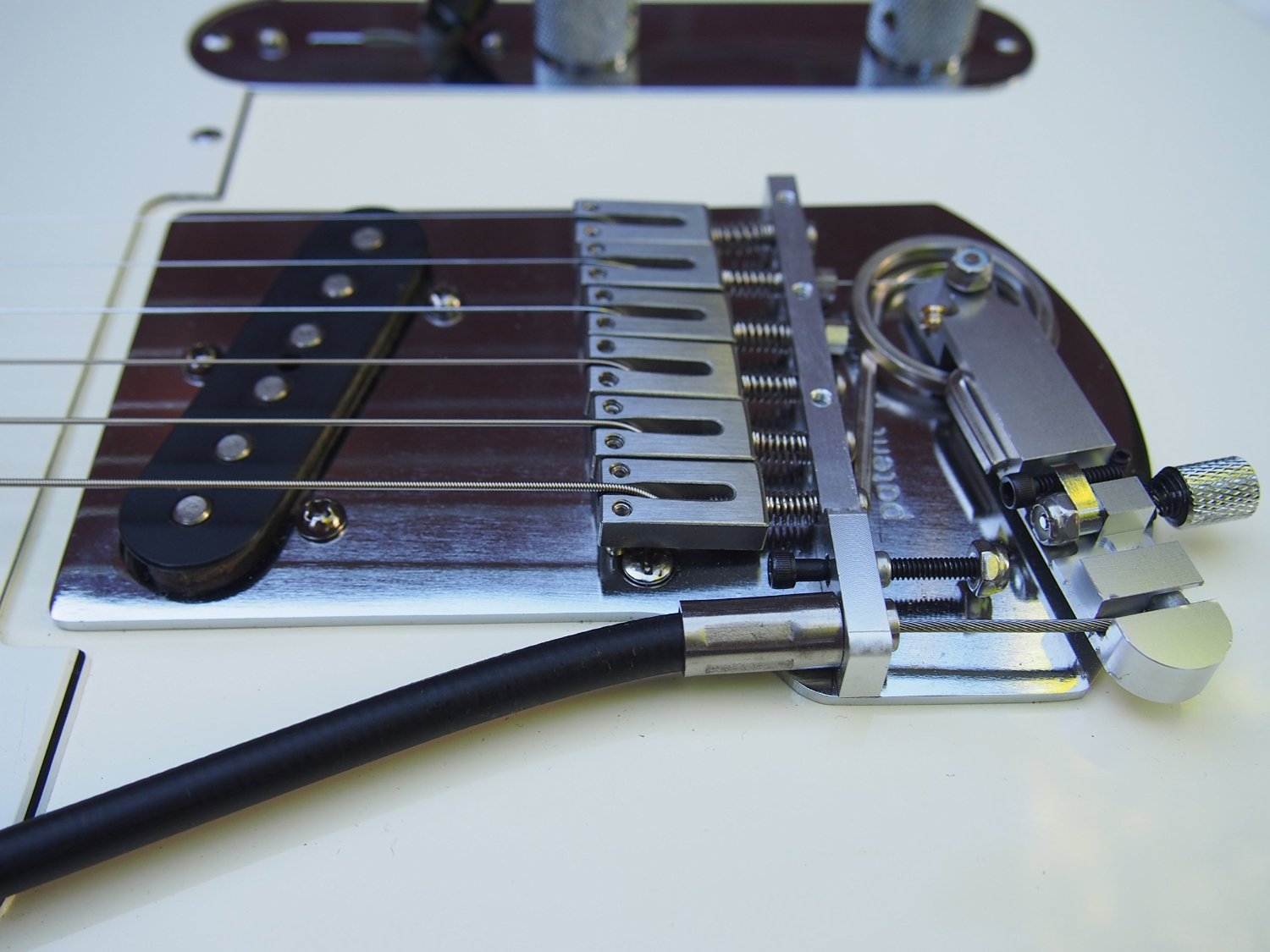

Fabricated

Some parts need to be produced through multi-process fabrication. Padtech's flexible manufacturing partners can produce parts using any of a number of processes including:

- Bending / Cutting

- Punch Press

- Progressive Stamping

- Laser Cutting

- CNC Milling and Turning

- Water Jet Cutting

- Welding

- Heat Treating

Additional services include:

- Anodizing, Hard Anodizing with Color Match

- Plating / Selective Plating

- Powder coating

- Chemical Etching

- Silk screen printing

Padtech specializes in industrial housings and tools in the metal fabrication market.

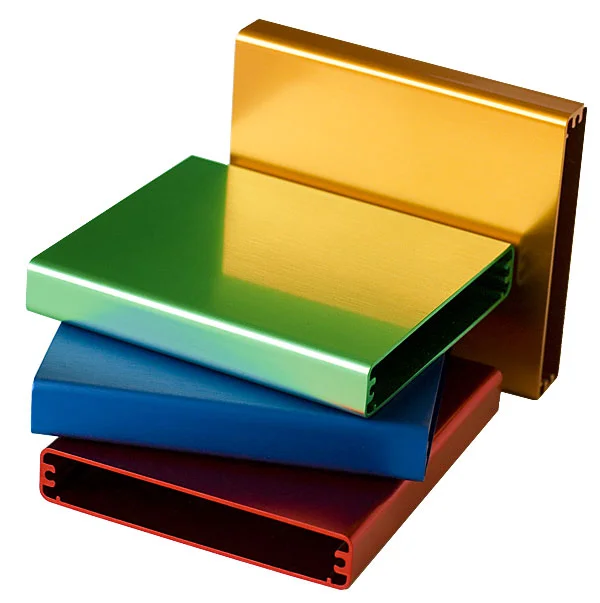

Extruded & Machined

Padtech provides exceptional quality metal extrusion and machined products with tool and dies to offer customers quick turnaround services. Additionally, we offer an extensive range of surface finishes – color and hard coat anodizing, powder coating and bright dipping.

Padtech’s metal extrusion and machining capabilities include:

- Tool and Die Manufacturing

- Post Extrusion Milling/Turning

- Surface Finishing

- Silk-screening

Cast & Machined

Padtech uses die casting to produce cost-effective high volume metal parts with aluminum, zinc and magnesium alloys. Our capabilities cover not only die casting, but also machining, finishing, plating, and painting.

Benefits of die casting include:

- Consistent quality even for high volume parts

- Cost-effectiveness in high volume parts

- Complex-shaped parts with high tolerances can be easily manufactured

- Longer tool life

Post-casting services include:

- Surface Finishing – shot blast, vibratory finish, thermal de-burr, clean, coat, plate or paint

- Machining – drill, ream, tapp, grind, etc.

- Join and Finish

- Assembly